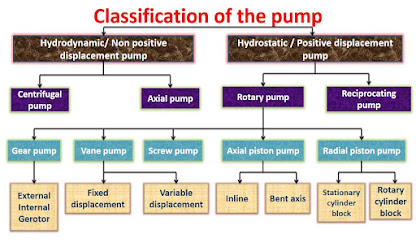

Hydrodynamic/non positive displacement pump:

- A Non-positive displacement produces a continuous flow/discharge and it uses Inertia of the fluid to displace or transfer the fluid flow.

- These types of pumps are generally used for low pressure and high-volume flow application.

- In this type of pump liquid velocity and movement is large, output pressure depends velocity with which the liquid is made to flow.

- Since these pumps are not capable of withstanding high pressure, these pumps are primarily used to transfer the fluid from one place to another place. Centrifugal(Impeller type) and axial flow(Propeller type) pumps are examples for this type.

- This type of pump is provided with greater clearance between rotary and stationary element hence this type of the pump is not self priming.

- Because it does not provide a positive internal seal against slippage its output varies according to the vary in pressure at outlet i.e. pump will give maximum output when the output pressure is zero, as pressure at output increased in the flow also decreases.

- The rotating parts of the imparts kinetic energy to the fluid. This pump make use of Newtons law of motion to move the fluid against system resistance.

- The volume of fluid delivered during each cycle will depend on resistance to flow of the system

- Closing the outlet of a non-positive displacement pump causes an increase of pressure. Because of presence of slippage this increase of pressure may not causes break down of component.

Advantages of NPD pumps

a. Low initial cost

b. Minimum maintenance

c. Noiseless operation

d. Capable of handling almost all type of fluids including sludge and slurries.

e. High reliability and Simplicity of operation.

Dis-advantages of NPD pumps

a. The positive displacement pump is not self priming.

b. The output per cycle varies.

c. Less efficiency & size is more

Comments

Post a Comment